Pages

17

SPECIFICATION

Labor and Materials Required in the workmanship and fitting up of a STEEL AND IRON JAIL, to be built and completed for

Per the accompanying plans, models or sections by the Diebold Safe and Lock Co., Canton, Ohio.

STIPULATIONS. 1st. It is expressly agreed and understood that the works mentioned herein shall be constructed in strict accordance with the plans, proposals and specifications for the same herewith submitted by the DIEBOLD SAFE AND LOCK CO., Canton, Ohio.

2nd. By and with the consent of both parties hereto, extra works and alterations during the contruction of the present work may, if deemed best be made, and the same shall not invalidate nor impair existing agreements, but contracts affected will be altered in time and amount at pro rata rate.

3rd. The Contractor will commence work as soon as notified of the award, or otherwise as directed, and thenceforward proceed with all possible dispatch to completion. The entire work to be performed in the most thorough and skillful manner, and all material to be sound and suitable for the purpose intended.

4th. The Steel used in this contruction shall be the improved 5-ply by Chrome Steel, which is warranted superior to any other by 50% or more, and has great advantages in hardness and tenacity over all other known jail or carbon steels. The bars or plates consist of alternate layers of steel and iron, uniformly welded and both metals united perfectly together. The gratings or bars are first fitted and the hardened, the steel receiving a temper that will resist any saw, file or drill, while the iron surface and centers remaining soft and ductile, will not break under heavy blows.

18

THE FOLLOWING GENERAL FEATURES SHALL BE PRESERVED IN THIS WORK, INCLUDING ALL MINOR DETAIL NECESSARY TO RENDER THE SAME FINISHED AND COMPLETE:

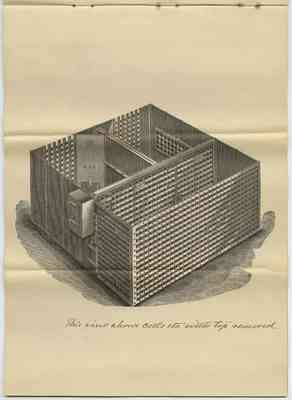

Dimensions Two (2) Cells arranged according to diagram, and each to be about 7'-6" high, x 6"-6" wide, x 8'-0" deep. The corridor will extend 5'-0" wide across the front of Cells and be the full height of same; other dimensions may be obtained from the drawings and the figures thereon.

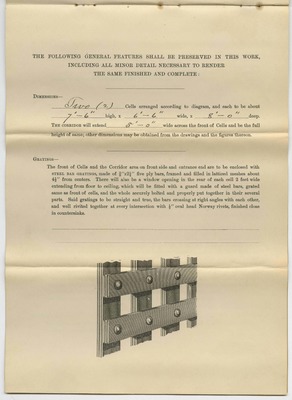

Gratings The front of Cells and the Corridor area on the front side and entrance end are to be enclosed with STEEL BAR GRATINGS, made 3/8" x 2 1/4" five ply bars, framed and filled in latticed meshes about 4 1/2" from centers. There will also be a window opening in the rear of each cell 2 feet wide extending from floor to ceiling, which will be fitted with a guard made of steel bars, grated same as front of cells, and the whole securely bolted and properly put together in their several parts. Said gratings to be straight and true, the bars crossing at right angles with each other, and well rivited together at every intersection with 1/2" oval head Norway rivets, finished close in countersinks.

[illustration of rivits]

19

Plates The remaining walls, also the floors and ceilings of cells and corridor, will be made of special 5-ply CHROME STEEL PLATES 1/4" in thickness, faced and edged to close joints, with retaining battens of 1/4x3 1/2" bars to form all overlaps. The partition wall between cells shall be made of rerolled plate iron 3/16" in thickness with 1/4x3" batten bars to cover joints.

Angles The connection around all inside corners will be made with 2"x2"x1/4" iron angles, with flanges neatly fitted both ways, all well fastened. The outside corners, upon which most dependence is placed for stability, will be covered with double angle iron 2 1/2" x 2 1/2" x 1/4", having our patent gored, bent and SOLID WELDED ANGLE CAPS around all double corners with 18" bearings at each end, all snugly put together and properly riveted.

Doors The Corridor and Cells will eachhave entrance ways fitted with doors to match the steel gratings. Eash door lbing put up inthe best manner, with all necessary fixtures complete for placing same in perfect working order, and made additionally strong by having an extra wide stiffenting bar rivited on full length of front and back. These doors to have our improved self-closing GRAVITY HINGES, set on steel facing plates and bolted to and through the framings in the most substantial manner, with proper flanges on the front for striking and with nosings on the back and sockets on the jambe to receive the reinforcing bars when shut. The doors also will each have a food hole of proper size at the bottom and be supported by strengtheing angles rivited on at back ofback of jamb to form an overhang finish.

Locks These doors to be furnished complete with all required latched, staples, etc., to secure and protect them when shut. A catch, to latch by weight of door will be properly attached to each, and, in addition to other fastenings, said doors will have our recenty patented JAIL LOCK BARS AND LEVERS, so adjusted as to close a shutter bar 3/8x3" over the entire front edge of door. This bar will be secured to jambs and covered with a steel bar 1/4x3", and operate with heavy wrought iron lever enclosed within a steel lintel bax over doors with all shafts, guides and guards to make same complete. These locking levers will extend back outside of prisoner's corridor and have handles locked inside of a GUARD BOX made of plate iron thouroughly put up and bolted to jailor's side of front corridor wall, within convenient reach from corridor door. The door of guard box to be secured with a 6 tumbler key lock and bolt work.

Hammock Supports Provide in each cell four sets of wrought iron angle brackets fastened to the wall in the strongest manner to support hammocks.

20

Ventilator Frunish and fashion ontoonecorner at the rear ofeachcell, a partition of No14 sheet iron for a ventilation shaft, and provide same with a sliding door, say,14x14", and arranged at the bottom to tkae in the usual siol bucket. Also make a movable slat register at top of flue with corresponding perforations in top of cell for draft.

Bucket Also furnish to eachcell or Ventilator a patent air-tight odorless night soil and Prison Bucket, made of malleable iron enamelled, with handle, etc., all of neat and durable construction.

Sink and Hopper Provide and put up in corridor area opposite the entrance end, a patent cast iron jail hopper and sink with all necessary traps and odorless catch basins connecting to 4" drain pipe outside and carried ___ feet in saome to street , sewer or cess pool. The whole to be set with proper brass cocks, globe valves and fittings to the water flushings and waste pipes with which the lavatory and hopper are to be connected.

Tank For the regular supply of water to the above, provide and set up in place on top if corridor outside directly over the sink etc., (to which is to be properly connected with pipes) a water tank 2x3'x3' feet in size, made of 2/16" tank iron, with angle iron flanged around the edges and all properly leaded, caulked and made water tight. The leader and overflow pipes may run down on the outside of wall if desired, with convenient outlets and stop cock to regulate the water supply and wastage.

Painting Prime all the ironwork with one good coat of brown mineral paint in oil before being brought to the building.