Pages

Page 19

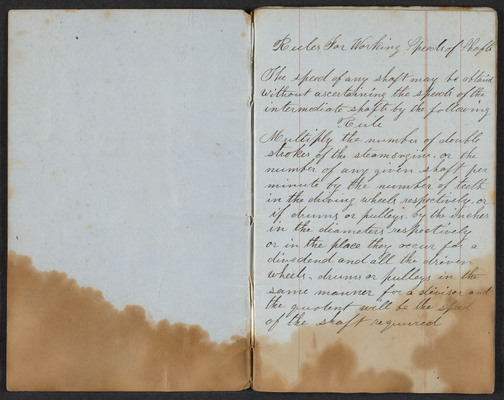

Rules for Working Speeds of Shafts

The speed of any shaft may be obtained without ascertaining the speed of the intermeditate shaft by the following Rule Multiply the number of double strokes of the steam engine, or the number of any given shaft per minute by the number of teeth in the driving wheels respectively, or if drums or pulleys, by the inches in the diameters respectively or in the place they occur for a divedend and all the driven wheels, drums or pulleys in the same manner for a divisior and the quotient will be the speed of the shaft required

Page 20

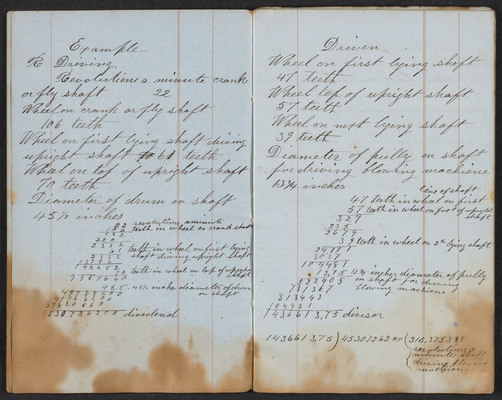

Example Driven Re Driving Wheel on first lying shaft Revolutiens a minute crank 47 teeth or fly shaft 22 Wheel top of upright shaft Wheel on crank or fly shaft 57 teeth 106 teeth Wheel on next lying shaft Wheel on first lying shaft driving 39 teeth upright shaft 61 teeth Diameter of pully on shaft Wheel on top of upright shaft for driving blowing machiene 70 teeth 13 3/4 inches line of shaft Diameter of drum on shaft 47 teeth in wheel on first 45 1/2 inches 57 teeth in wheel on foot of upright shaft 22 revolution aminute 329 106 teeth in wheel on crank shaft 235 132 2679 220 39 teeth in wheel on 2nd lying shaft

Page 21

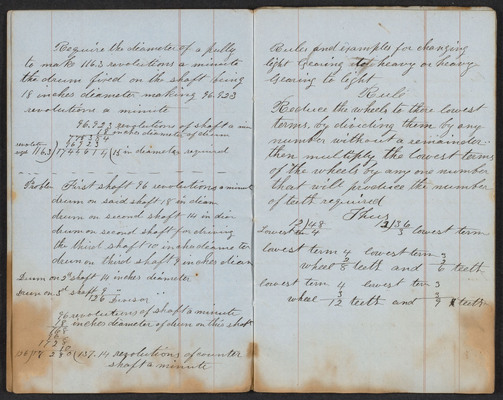

Require the diameter of a pully to make 116.3 revolutions a minute the drum fixed on the shaft being 18 inches diameter making 96.923 revolutions a minute.

96.923 revolutions of shaft a min 18 inches diameter of drum ----- 775384 96923 ----- revolution [reqd?] 116.3) 1744614 (15 in diameter

- - - - - - - - - - - - Problem. First shaft 96 revolutions a minute drum on said shaft 18 in diam drum on second shaft 14 in diam drum on second shaft for driving the third shaft 10 inches diameter drum on third shaft 9 inches diam Drum on 2nd shaft 14 inches diameter Drum on 3rd shaft 9 " " ----- 126 [?]

96 revolutions of shaft a minute 18 inches diameter of drum on this shaft ----- 768 96 ----- 1728 10 ----- 126) 17280 (137.14 revolutions of counter shaft a minute

Rules and examples for changing light gearing to heavy or heavy gearing to light

Rule Reduce the wheels to there lowest terms, by directing them by any number without a remainder then multiply the lowest terms of the wheels by any one number that will produce the number of teeth required

Thus (2) 48 ----- lowest term 4 (3) 36 ----- 3 lowest term lowest term 4 lowest term 3 wheel 2/8 teeth and 2/6 teeth lowest term 4 lowest term 3 wheel 3/12 teeth and 3/9 teeth

Page 22

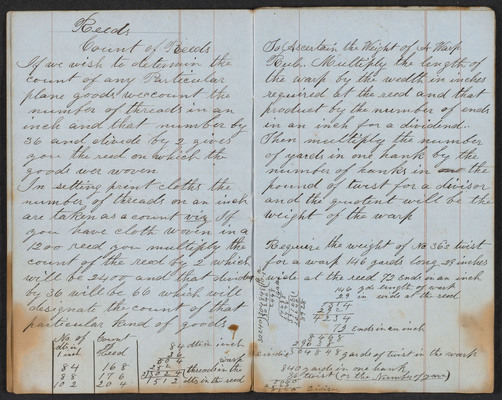

Reeds Count of Reeds If we wish to determin the count of any Particular plane goods we count the number of threads in an inch and that number by 36 and divide by 2 gives you the reed on which the goods wer woven. In setting print cloths the number of threads on an inch are taken as a count viz If you have cloth woven in a 1200 reed you multiply the count of the reed by 2 which will be 2400 and that divided by 36 will be 66 which will designate the count of that particular kind of goods. [Table] To Ascertain the Weight of A Warp Rule.. Multiply the length of the warp by the wedth in inches required at the reed and that product by the number of ends in an inch for a dividend.. Then multiply the number of yards in one hank by the number of hanks in one the pound of twist for a divisor and the quotint will be the weight of the warp

Require the weight of No 36's twist for a warp 146 yards long 29 inches wide at the reed 72 ends in an inch [Table]